Cannabis Formulations – Emulsifying VG and BHO for Tinctures

As cannabis use elevates in popularity, the demand for non-combustible products simultaneously grows. In the current industry, both medical and recreational sales are moving away from traditional herb and into the realm of edibles, vapor juices and tinctures. The latter of the three is popular among those who need precise and regular cannabis dosing. However, the usage of tinctures is growing among recreational consumers as it offers the therapeutic benefits of cannabis without having to smoke the herb or consume edibles.

Although the popularity of cannabis tinctures is growing, the methodology adopted by numerous manufacturers is problematic and delivers inconsistent results. The most notable issue is ingredient immiscibility. Vegetable glycerin and BHO is notorious for its inability to easily emulsify. Moreover, an improper emulsification often results in ingredient separation after processing.

At CAT Scientific, we’re dedicated to the success of cannabis-based businesses and the evolution of high-quality products. To rectify the issue of immiscibility in non-alcohol tinctures, we’ve created a simplified – and effective – emulsification process. Our processing techniques takes only two hours and doesn’t require the use of a surfactant, such as lecithin.

Effective Emulsification | Simplified Guide for VG and BHO Tinctures

To demonstrate the effectiveness of our process, CAT Scientific received 25 grams of winterized and decarboxylated BHO absolute from a cannabis processing company. We used the following pieces of equipment:

- CAT X1000D Homogenizer Drive | The power of the X1000D Homogenizer Drive offers an appropriate level of torque to process VG and BHO, which has notoriously high viscosity and demands significant power to be properly blended.

- G-20(N) Normal Generator Shaft Assembly | With a sealed design, this shaft streamlines processing as the operator doesn’t have worry about the solution entering the shaft tube or cross contamination. Its sealed design makes for simple cleanup and prolonged use as the tube interior isn’t exposed to solution ingredients.

- CAT MCS78 Magnetic Hotplate Stirrer | Used to heat the vegetable glycerin with pinpoint accuracy.

Step One | Heating the Ingredients

Using the CAT MCS78 Magnetic Hotplate Stirrer, we placed 500ml of kosher vegetable glycerin in a one-liter beaker and set the temperature to 80°C. In a separate vessel, we also heated the BHO absolute.

Step Two | Homogenizing the Ingredients

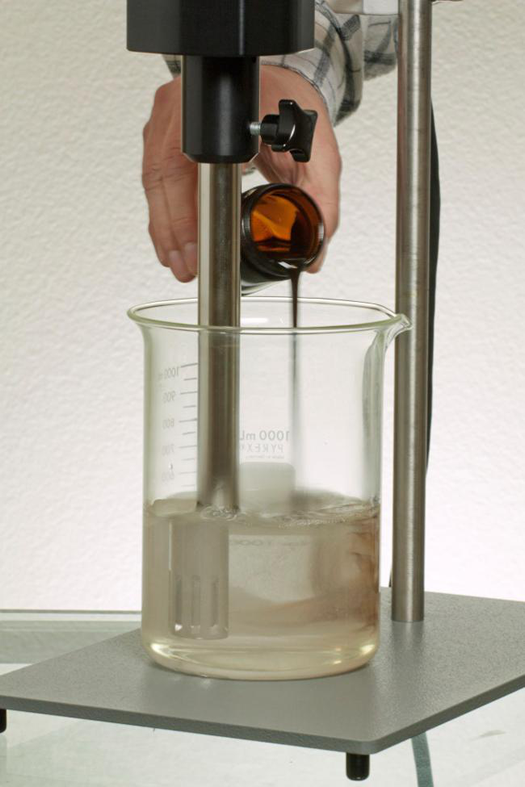

Once the ingredients reached 80°C, we moved it into the X1000D Homogenizer with the G-20 (N) Generator attached. The X1000D is clamped to the drive stand and the Generator Shaft is immersed until it’s roughly 1/16th of an inch from the bottom of the vessel.

We turned on the homogenizer to 4,000 RPM’s and slowly increased its speed to 8,000 RPM’s. Once the VG has reached its optimum speed, we carefully poured the BHO absolute into the solution, which is allowed to stir for 45-60 seconds. After a maximum of one-minute, the device is deactivated.

Step Three | Heating the Solution

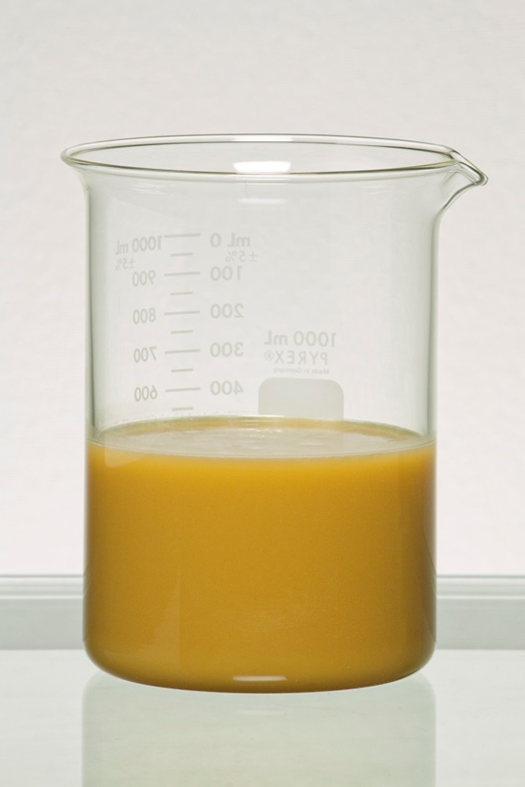

After the device is powered off, we removed the beaker from the homogenizer drive and placed it back on the hotplate stirrer and heated to 80°C for 30 minutes. Throughout the heating time, some BHO absolute can destabilize and fall out of the solution and appear in the center of the vessel.

Step Four | Second Round of Processing

To emulsify the destabilized BHO, the solution is returned to the X1000D and processed at 8,000 RPM’s for 45-60 seconds. Once again, we moved the solution to the hotplate stirrer and reheated it to 80°C for 30 minutes. Should any BHO fall out of solution, repeat with the emulsification and heating process until the solution is fully stable. Once completed in this process, our VG-BHO solution was stable for roughly 90 days.

CAT Scientific | Simplified Solutions for Modern Cannabis Processors

As the cannabis industry evolves, so does the need for powerful, efficient and predictive processing techniques. CAT Scientific believes every manufacturer should have the tools and knowledge to provide patients and consumers with the highest-quality product. We’re here to answer any and all questions you may have about this and other processing needs.

Contact Us today to see how we can work together to make the cannabis indu

stry a better and safer experience for all!

Preheat VG to 80°C

X1000D Homogenizer Setup