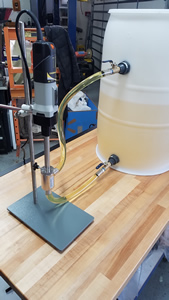

X1000 Homogenizer with DK30 Flow-Through-Chamber Attachment

How to Turn a Lab Homogenizer into an Inline Device

Laboratory homogenizers represent a significant investment for research organizations engaged in developing new processing procedures across a broad range of industries. Integrating or adding a flow through chamber to the homogenizer mixer greatly increases its functionality by enabling inline processing or extending the exposure of samples to the homogenization action.

This post provides

- An introduction to lab homogenizers

- A description of flow-through chambers

- Tips on using lab homogenizer flow-through chambers

- Important cleaning and maintenance for flow through chambers

What is a Lab Homogenizer?

Lab homogenizers offer outstanding versatility as tools to homogenize, emulsify, disrupt, mix, blend, macerate and otherwise process materials to support R&D, establish pilot plant production procedures and similar activities across a broad range of industries.

They come in various models generally classified by power in watts, controllable speeds in thousands of revolutions per minute and processing capacity. The latter, for example, can range from 0.1 mL to 20 liters in test tubes or beakers.

Homogenizers consist of a generator assembly comprised of a slotted stator affixed to a compatible generator tube available in various lengths.

The tube encases a compatible shaft (or axle) to which is attached a rotor that fits into and matches the function of the stator. The assembly is fitted into the homogenizer motor (or driver) that drives the axle and rotor at user controllable speeds to 45,000 rpm.

When the generator is put into a container and turned on the rotor draws material into the assembly and whips it through the stator slots thereby achieving homogenization.

As the homogenizer continues to operate all of the material in the container will pass through the rotor-stator assembly to be processed, the time depending on the size of the container and the objective of the homogenization activity.

To provide stability during the homogenizing process the equipment is clamped to a mounting stand. The stand also supports beakers and flasks containing material being processed.

Together these components comprise a modular homogenizing system.

What is a Flow-Through Chamber?

As described above, in a conventional lab homogenizer scenario samples remain in the flask or beaker. They are continuously drawn into and discharged from the homogenizer rotor-stator assembly.

The only control researchers have is the speed of the homogenizer drive motor and the length of processing time in the test tube or beaker. In other words, conventional homogenizing procedures provide no means of transferring the samples from point A to point B or, to otherwise state, support inline processing.

Flow-through chambers are most simply defined as pumps that draw samples through an inlet tube to a generator assembly and dispense it either back into the same container or to another container via an outlet tube. By restricting the flow through the outlet, dwell time in the generator is increased for enhanced processing.

Flow-through homogenizer chambers can also be used for closed-loop processing by isolating the material from the environment, and by continually circulating material by directing the outlet tube into the same container.

Tips on Using Lab Homogenizer Flow-Through Chambers

- Extend Homogenization Dwell Time

Couple a CAT Scientific DK30 stainless steel flow-through chamber to CAT G 20 or G 30 homogenizing dispersing tools (respectively 2000 and 3000 liter capacities) and operate the homogenizer drive motor in the same way you would for standard emulsifying and dispersing.Material is drawn through clamped tubing into the bottom inlet and processed by the rotor-stator then discharged through clamped tubing from a side outlet either back to the beaker or to another container. Dwell time in the flow through chamber is controlled by restricting the outlet flow.

- Use Flow-Through Chambers for In-Line Homogenizing-Mixing

We suggest the CAT DK40 (5,000 liters/hour) flow-through chamber. This unit is designed to pair with the CAT X1740 1500-watt homogenizing system driver that operates to 23,000 rpm.The mounting flange of the DK40 is attached to a horizontal plate and accepts the X1740 motor flange so that the driver is firmly fixed in the horizontal position. Note that attaching the driver is the final step after assembling the chamber.An axle sized to the DK40 system is inserted into the mounting flange and will snap into the driver.The cooling-jacket-equipped flow-through chamber housing includes the sample outlet, the coolant inlet and outlet. Subassemblies include a chamber lid snugged against the mounting flange, a stator, rotor and inlet chamber lid.O-rings are fitted at appropriate locations. The chamber assembly is firmly attached to the mounting flange by means of wing nuts.Attach and clip the inlet and outlet tubes, routing as needed. Attach coolant circulation tubes if the samples are affected by heat.

Caution: This system is not self-priming. The inlet tube and flow-through chamber must be filled before the homogenizing process is initiated. Place the sample container at the same level as the chamber and be certain that the sample enters the chamber before turning the drive motor on.

With this in place you’re ready to start in-line processing via a lab homogenizer.

Please refer to the Cat Scientific X1740 user manual for complete details on the DK40.

How to Clean and Maintain Flow Through Chambers

After each use all flow-through homogenizer chambers must be flushed out by pumping a suitable cleaning solvent through the mechanism to remove traces of material being processed before it dries on the mechanism components. Cleaning instructions are provided with manuals.

We also invite you to view our post on Cleaning Tips for Homogenizers and Emulsifiers.

For complete information on CAT Scientific homogenizer components contact us or complete and return our Homogenizer Questionnaire.

You can read further in the article How To Use the CAT Homogenizer Flow Through Chambers.